| This topic is available here on The Repair-Place forum |

I was reading some instrcutions on how to put up some decorative trim and it said to make a "scarf cut", then it talked about the "scarf joint".

What's are scarf cuts and scarf joints? |

|

|

A scarf joint is a type of "end joint" gluing. End joint gluing of lumber is the method for producing long length stock for your application. In this book's example it was for decorative trim. This means that the length of the piece of trim wasn't long enough.

Although there are a number of types of end joints, the three most common types are scarf, butt, and finger joints.

Butt joints are the worst. They are formed merely by butting the squared ends of material to be joined. Even a well prepared glued butt joint will exhibit at the most 25 percent of the tensile strength of clear lumber.

Consequently, butt joints are seldom used for any projects.

Scarf joints are made by cutting the ends of lumber to fit each other and subsequently securing them together by overlapping and gluing.

A well designed scarf joint, will exhibit tensile strengths of 65 to 90 percent that of clear lumber. That depends on the "slope" of the joint. For a glued joint to be as nearly as strong as the base wood, it must have a slope of 8 to 1. In other words, if your stock is 1" thick, you need to make a joint 8 inches long.

Here is a structural scarf joint:

Note: The slope on this joint is not 8 to 1 because the support is directly under the joint.

For a non-structural scarf joint, a slope of 1 or 2 to 1 is fine. You just want to give enough surface area for the glue to hold, and it makes the joint almost unnoticeable. Also in the case of a non-glued joint, if there is slippage it won't be as noticeable.

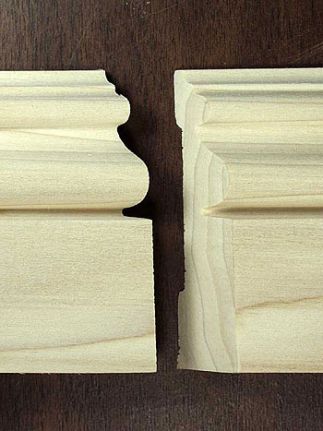

Here is a decorative scarf joint:

Finger joints are a series of fingers machined on the ends of two pieces to be joined which then are fitted together and held in place by glue. Specialty Jointing equipment is required to make the exacting cuts needed for a successful finger joint. They are mainly employed by commercial mills, and in decorative trim, are used to make inexpensive, designed-to-be-painted moulding. |

If the scarf joint is made using unfinished molding then the joint would need to be sanded using contoured sanding grips. They are rubber shaped handles that you put sandpaper around. They come in different sizes and shapes, so you can sand concave and convex profiles.

You can get a complete set of 12 contoured sanding grips at Woodcraft for about $10.00. They also have smaller sets of 4 or 5 different profiles for about $5.00

If you are making a scarf joint in prefinished molding, then you just have to make the joint correct the first time! |

Sanding intricate molding is extremely challenging, if not impossible, using ordinary sanding methods. So if you need to sand a molding that won't match the available profile sanding blocks, you can make one yourself that fits perfectly!

To make a sanding block that perfectly matches the profile, or a section of the profile if it is a larger one, put Saran wrap or any plastic food wrap, over the section of the profile you want the block for. Leave about 6" extra all the way around. Make sure it is smooth and doesn't have any folds. Mix any two-part automotive auto body filler like 3M Lightweight body filler or Bondo, and carefully put it on the plastic wrap. Carefully fold the extra wrap around the filler and let the filler stiffen into a block (it will get slightly hot as it stiffens). After about half hour, your new custom profile sanding block will be hard and ready to use! |

Cool idea!

Could you sprinkle some sort of sanding grit right into the Bondo? |

Hmmmm! That could be the tip of the month winner right there!! You get the free T-shirt!!

I'll have to try that out and let everyone know. First I need to figure out what the grit material is that I would need to use.

The grit would be sprinkled onto the Saran plastic wrap before the bondo goes on I would think.

When it does wear out then regular sandpaper would 'stick' better to the new shaped block too!

Thanks! |

Boy this topic has taken a left turn!

Back to scarf joints.... There is a way to connect molding or flat boards without scarf joinery.

If the two pieces of wood to be joined are thick enough, then you can use a Lamello 101250 C2 Classic Plate Joiner (about $350.00 on line) to accurately align the two pieces and then put a little glue with a beech wood biscuit to hold them permanently together. The biscuit swells up slightly when the water based glue is used so the joint is incredibly strong. This does require some sort of clamping or pressure until the glue sets up.

OR you could use the Kreg Jig (about $150.00 for their complete kit on line). This tool drills a special sized hole at the correct angle into one of the pieces so that when a screw is put in it grips the second piece. This is done from the back and does not require glue or clamping at all. In fact the joint is so strong it can't be pulled apart without breaking the wood itself.

I have both tools but prefer the Kreg jig over the Lamello Plate Joiner, unless both sides of the work piece will show or I would need to make a cut where the Kreg screw would be. |

Dowling a Kreg Joint + Glue

Quote:

I have both tools but prefer the Kreg jig over the Lamello Plate Joiner, unless both sides of the work piece will show or I would need to make a cut where the Kreg screw would be. |

I plan on making an Irish Drum (Bodhran)

I've heard of using a 5/16" dowel in place of the Kreg screw.

Of course, I wouldn't want to cut that joint... but I was wondering about the strength of a doweled joint? ...still stronger than the wood?

Also, what types of glue do you recommend for best success???

Non-toxic and otherwise.

Thanks!

Looking forward to making my Irish Drum (Bodhran)! |

I wouldn't think a Bodhran drum would use any fasteners at all. The rim is best bent from a single piece or laminated from several thin pcs of thinner wood. see catdreams.com/bodhran/Bodhran.html

Good luck! |